Bowen Li, Yinlong Zhu*, Wanlin Guo. Inorganic Chemistry Frontiers(2023)

Abstract:

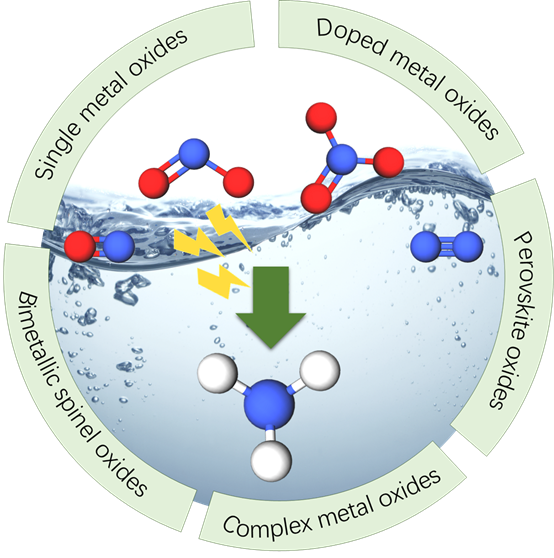

World ammonia production is reaching 235 million tons in 2019, and roughly 88% of NH3 produced goes into agriculture section as fertilizers. Industrial ammonia production relies on the Haber-Bosch process, which is highly energy demanding and results in high CO2 emission. More than 1% of global energy generation was required to power this Haber-Bosch process. While sustainable development has become a general consensus across the globe, there have been enormous research interests toward possible modification or replacement of the Haber-Bosch process, aiming to reduce the environmental impact of NH3 production. With the successful commercialization of various renewable source powered electricity generation techniques, electrochemical reduction of nitrogen containing chemicals (including N2, NO3-, NO2- and NO) to produce NH3 under ambient conditions has emerged as a potential green alternative to the Haber-Bosch process. This technique utilizes renewable electricity to achieve small-scale, on-site and on-demand ammonia production, serving as a critical contribution to overall carbon neutral economy. Design and synthesis of novel catalysts with high NH3 production rate and selectivity is the key challenge in determining the economic feasibility of this electrochemical NH3 production. In view of the rapid and fruitful development of metal oxides as promising electrocatalysts toward NH3 formation, this review summarizes different types of metal oxides used for electrochemical N2 reduction reaction and electrochemical NOx reduction reaction, together with design strategies to enhance their catalytic performance. As a concluding remark, our thoughts are given on the critical challenges in this field, suggesting possible future research directions to accomplish industrialization for electrosynthesis of NH3.

Link: https://pubs.rsc.org/en/content/articlelanding/2023/QI/D3QI01448G